This article is about the typical printing or packaging company whose pricing strategy is heavily influenced, and in some cases controlled by the estimating department.

Estimating is a critical part of the sales process. When a customer requests a price quote, a cost estimate is created by an estimator to help determine the price. If your company is fortunate enough to have one of the few remaining experienced estimators, then you’re confidence they will create an accurate time, material, and cost estimate that can be used to competitively price the job. Or are you?

A seasoned estimator will have an understanding of production processes and how long it should take to produce a job. But an estimator is only as good as the tools and information they are given.

Most printing companies use some form of estimating software to create estimates. These estimating programs rely on databases of production equipment standards and budgeted hourly cost rates (BHRs) to generate time, material, and cost estimates. If your equipment standards and cost rates are outdated or inaccurate, so are your estimates.

A business’ costs and standards are constantly changing as production equipment is added or replaced, new processes and procedures are implemented, personnel change, and expenses increase or decrease. Nevertheless, many companies fail to keep their standards and cost rates up-to-date and indiscriminately churn out inaccurate estimates potentially resulting in losing over-priced work and winning below-margin orders.

True Cost EstimatesTo ensure you’re producing accurate true cost estimates and competitively pricing jobs, your equipment standards and hourly cost rates should be regularly updated to reflect your plant productivity and actual costs.

Production standards can be monitored and updated with the help of shop floor data collection and job costing software. Meetings should be facilitated at least every 6 months with the estimators, production, and cost analyst to review and synchronize the estimating standards with actual production makeready, setup, and running speeds and waste.

Additional meetings should be facilitated at least semi-annually with accounting to align the estimating equipment budgeted hourly cost rates with actual company expenses including operating costs, wages, rent, utilities, depreciation, insurance, overhead, and other costs.

BHR software such as CostRatesAdvisor.com makes it easy to calculate your equipment cost rates so you’re always recovering costs. Cost Rates Advisor automatically calculates the break-even costs of your equipment based on your expenses, employee wages, assets, and costs. Financial information can be imported making it easy to keep your rates updated and saving hours of manual entry.

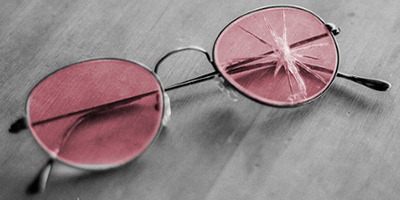

ConclusionTake off those rose colored glasses and produce accurate and trustworthy estimates that clearly reflect your true costs. You’ll be able to confidently and strategically estimate and price jobs, improve your competitiveness, and increase sales and profits. .